About eldris

epr.eldris.ai leads the EPR sector, in fast, automated, AI Agent EU Complaince. LUCID Packaging, WEEE, and Battery Compliance for Brands, E-Commerce and Service based businesses expanding into the EU.

In This Article

- Determine if your products with embedded batteries fall under the 2025 EPR scope.

- Ensure labels meet multilingual, chemical, and symbolic compliance across all target markets.

- Register and report accurately in every EU country where your product is sold.

- Appoint a qualified EU Responsible Person if your business operates outside the bloc.

- Avoid common pitfalls such as misclassification and incomplete submissions.

- Automate EPR compliance tasks to reduce human error and improve efficiency.

- Stay current on unique national obligations, especially in France, Germany, and the Netherlands.

Introduction: Why EPR Compliance Matters in 2025

Overview of Regulatory Changes

As Extended Producer Responsibility (EPR) legislation tightens across Europe and other global regions, compliance in 2025 is no longer optional for manufacturers and distributors of electronic products—particularly those containing embedded batteries. EPR compliance refers to the legal obligations placed on producers to take responsibility for the entire lifecycle of their products, including take-back, recycling, and disposal. By 2025, EU directives and national laws mandate strict traceability, labelling, and reporting requirements. These developments aim to reduce environmental harm, promote circular economies, and shift waste burden from municipal authorities to producers. Failure to meet EPR compliance requirements can now result in harsh financial penalties, restricted market access, or bans on sales.

Scope of Embedded Battery Products Under EPR

Applies to Smartphones, Wearables, and More

The scope of EPR compliance has expanded significantly to include a broad range of electronic devices embedded with batteries. In 2025, smart devices such as smartphones, smartwatches, fitness trackers, tablets, laptops, e-readers, and even medical wearables must comply with detailed EPR specifications. Products with sealed lithium-ion or nickel-metal hydride batteries are now especially targeted, due to the hazardous nature of these components and the difficulty of recycling them. Moreover, manufacturers must clearly identify every device that contains a battery component, regardless of whether the battery is removable by the end-user.

Product categorisation under the Waste Electrical and Electronic Equipment (WEEE) directive has also become stricter. This means that if a device contains any electronic function combined with a power source, such as embedded battery cells, it likely falls under EPR regulation. Furthermore, even accessories like wireless charging cases, Bluetooth-enabled headphones, and gaming controllers are now regulated under the updated framework. Producers must therefore assess their entire product portfolio to verify compliance obligations.

“The inclusion of embedded batteries means previously non-regulated products are now subject to full EPR enforcement.” – European Recycling Authority

New Identification and Labeling Requirements

One of the most substantial updates in EPR compliance legislation involves mandatory identification and labelling of products containing embedded batteries. As of 2025, every device falling under the directive must display visible, legible, and indelible markings that indicate the type of battery used, recycling instructions, and the producer’s identification number. Most importantly, the crossed-out wheeled bin symbol, combined with chemical markings such as “Cd”, “Hg”, or “Pb”, is required when relevant.

For embedded batteries specifically, the European Commission mandates clear disclosures regarding the battery type even if the end-user cannot access it. This information must appear both on the product (or its packaging) and on the digital product page. QR codes linking to environmental data are gaining popularity as a compliant solution. Labels must meet the language and localisation rules of each country in which the product is sold, requiring multilingual compliance protocols.

Registration and Reporting Obligations

Registering with the proper national authorities is a cornerstone of EPR compliance. Each European member state requires manufacturers, importers, or “distance sellers” to enrol with its national EPR schemes to track the quantity, type, and flow of regulated electronic products placed on the market.

Producers must ensure yearly—and in some jurisdictions, quarterly—reporting to fulfil legislated responsibilities. These reports generally require a breakdown of unit quantities, weight classifications, battery chemistries, and origin of manufacture. Failure to provide accurate and timely reports may result in legal sanctions or suspension of market rights. In countries like France and Germany, producers must also clearly assign responsibility to an “authorised representative” when selling cross-border, especially if they lack local operations themselves.

Using platforms that integrate EPR tracking and automate document submissions is advisable and significantly reduces administrative errors. Learn more about EU Extended Producer Responsibility for Electronic Products

End-of-Life Responsibilities and Recycling Paths

Producers are now responsible for the entire downstream lifecycle of embedded battery electronic products. In 2025, simply placing compliant products on the market is not sufficient. Manufacturers must fund and facilitate collection schemes to ensure proper recycling and processing of hazardous materials like lithium, cadmium, or lead.

In practical terms, this means participating in national recycling organisations or forming partnerships with authorised e-waste recyclers. These partners must maintain advanced capabilities to dismantle complex products without causing environmental damage. Additionally, battery take-back schemes must be publicly available to consumers, and details of return locations and processes must be listed on the manufacturer’s website.

Consumers are increasingly aware of their environmental footprint, and offering visible recycling paths enhances brand image while satisfying legal mandates. Some forward-thinking producers are also introducing cash incentives for consumers to return used devices, thus boosting collection targets.

Role of EU Responsible Person for EPR Compliance

For companies selling into the EU from outside the bloc, assigning an EU Responsible Person (ERP) is critical. This representative serves as the legal conduit between the non-EU producer and the relevant national enforcement bodies. As per the updated Waste Framework Directive, the ERP is responsible for registration, reporting, documentation retention, and sometimes product recalls.

The ERP must be established before any regulated item is introduced into any EU market. The Responsible Person must also be contactable by consumers for environmental queries and serve as the product’s legal contact. Practical selection criteria include availability, language competence, and expertise in handling cross-jurisdictional EPR tasks. Read a related article This requirement has become particularly relevant due to Brexit, as UK firms must now operate separate ERPs for the EU and Great Britain.

Common Compliance Mistakes to Avoid in 2025

Several recurring errors jeopardise EPR conformity. Chief among them is underestimating product categorisation. Manufacturers often misclassify products or assume their minimal battery capacity exempts them from regulation. However, if a battery is embedded and capable of powering an electronic function, then the product almost certainly falls under the EPR umbrella.

Another widespread issue is incomplete registration, especially among third-party sellers on marketplaces. Platforms like Amazon and eBay increasingly require EPR numbers but do not offer back-end registration services. Sellers mistakenly assume platform compliance is sufficient, when in fact, the obligation rests with the brand owner or importer.

Failing to assign a designated EU Responsible Person, omitting chemical composition from product labels, and missing country-specific deadlines are also frequent errors that can result in legal penalties or product delisting from marketplaces.

How to Automate EPR Reporting Workflows

EPR compliance can be time-consuming, especially when managing multilingual regulations across multiple jurisdictions. As a result, forward-looking manufacturers are turning to automation platforms to streamline documentation, reporting schedules, and multi-country obligations.

These tools integrate with ERP systems and centralise compliance data to avoid duplication or data entry errors. Automated reminders for report submission deadlines, database synchronisations with national registries, and real-time dashboards for compliance tracking are among the most valuable benefits.

Furthermore, some software providers combine EPR compliance with RoHS, REACH, and SCIP database workflows to give a holistic view of environmental obligations. Investing in automation not only reduces operational risk but also ensures enduring legal adherence. US Environmental Protection Agency’s EPR framework for batteries

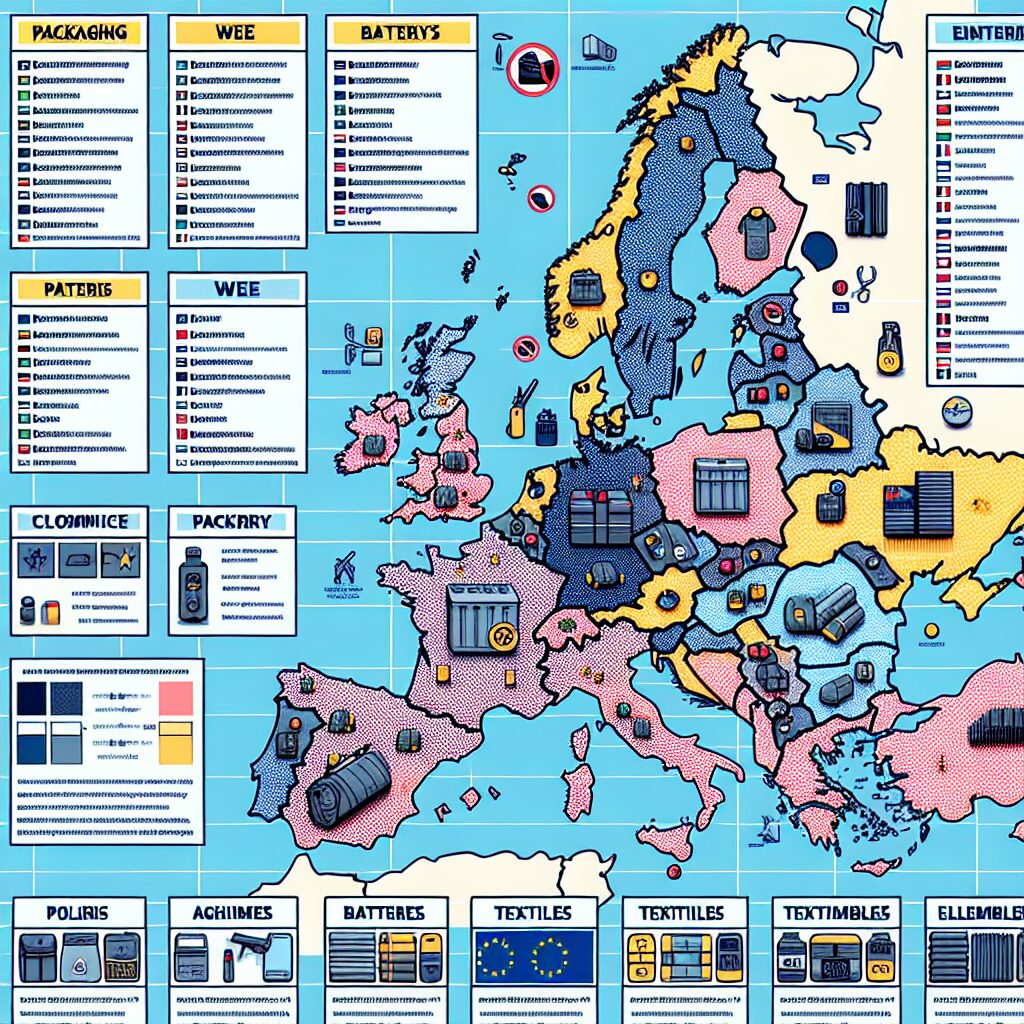

Country-Specific Notes: France, Germany, Netherlands

Each EU member state enforces EPR differently, and producers must deeply understand country-specific rules to ensure accurate compliance. France, under the ADEME framework, has introduced new EPRTriman symbols tied to specific categorisation groups. Moreover, EPR compliance in France now requires eco-modulation declarations, linking environmental impact to financial penalties or credits.

Germany, under the Stiftung EAR system, focuses heavily on transparency and uses a sophisticated registry known as “LUCID.” All producers—even those listing items via online platforms—must register and report independently. Country labels must be in German, and recycling scheme participation is compulsory.

The Netherlands, meanwhile, mandates contributions to Stichting OPEN for WEEE categories and has strict battery declarations under the Nationaal (Nationale) Wecycle scheme. Failure to accurately submit EPR product volumes can result in backdated billing or licence withdrawal. EU Responsible Person role for EPR obligations

Conclusion: Prepare Early for Success

[CONCLUSION_CONTENT]

Great guide on epr-compliance-embedded-batteries-electronics-2025-guide – Community Feedback

Who is responsible for embedded battery EPR compliance in the EU?

In the EU, producers—manufacturers, importers, and sellers—of electronics with embedded batteries are responsible for ensuring EPR compliance, including registration, labelling, and reporting.

What new EPR requirements apply to embedded batteries in 2025?

From 2025, stricter identification, collection, and reporting obligations apply to all electronics containing batteries, with enhanced labelling and recycling rules to meet EPR regulations.

How can sellers automate EPR compliance for embedded batteries?

Sellers can use automated compliance solutions to handle EPR registration, data reporting, and documentation for embedded batteries, streamlining obligations and preventing costly errors.