About eldris

epr.eldris.ai leads the EPR sector, in fast, automated, AI Agent EU Complaince. LUCID Packaging, WEEE, and Battery Compliance for Brands, E-Commerce and Service based businesses expanding into the EU.

In This Article

- Understand how EPR regulations directly affect EU WEEE margins across product and packaging types.

- Optimise classification to prevent costly misreporting and unnecessary tariff burdens.

- Use automation to streamline reporting, detect inefficiencies, and ensure compliance in all markets.

- Continuously reassess supply chain strategies to reduce volumes and materials subject to EPR charges.

- Engage with local scheme partners or regional consultants to fully leverage legal allowances and schemes.

Understanding WEEE and Packaging Compliance in the EU

Key EPR Regulations You Must Know

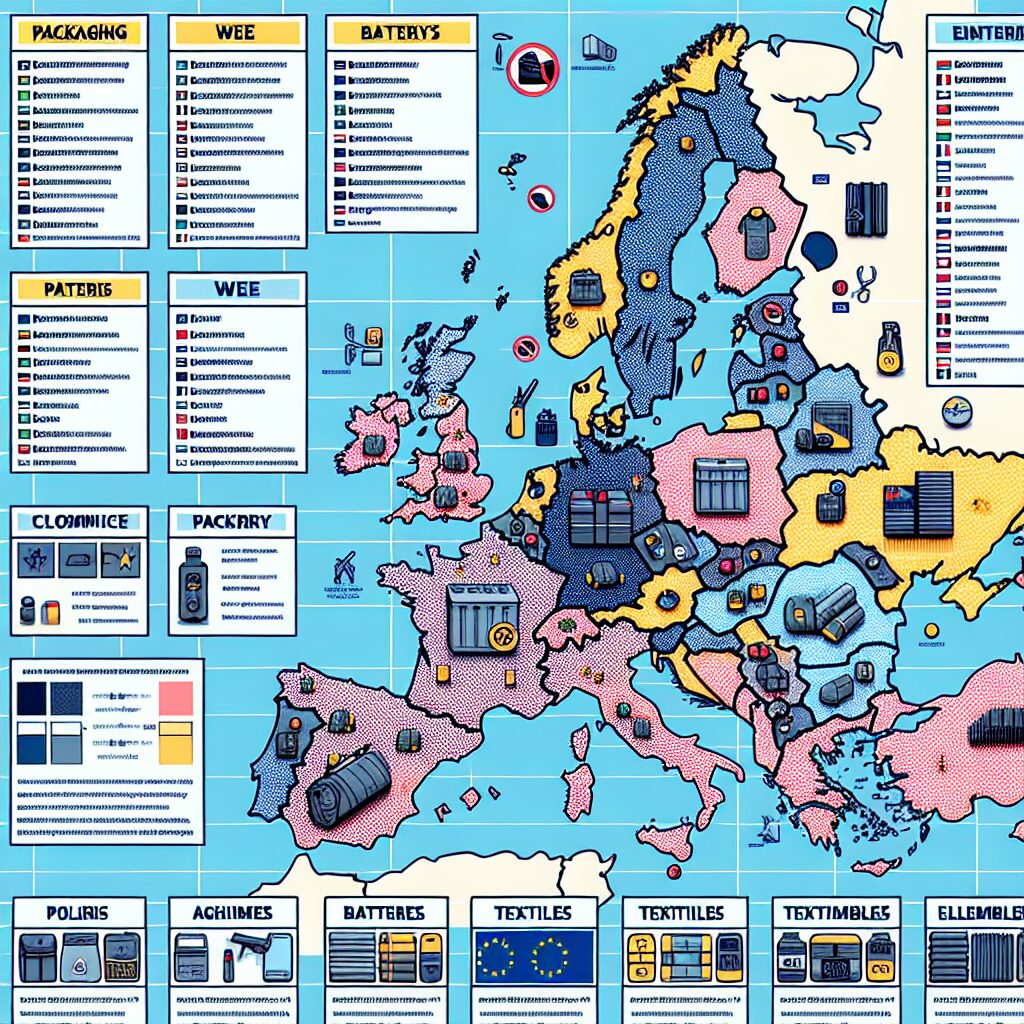

The concept of EU WEEE margins stems from the broader framework of Extended Producer Responsibility (EPR), which forms the backbone of sustainability legislation across the European Union. Specifically, the Waste Electrical and Electronic Equipment (WEEE) Directive mandates that producers are financially and administratively responsible for the collection, recycling, and disposal of electronic goods at the end of their lifecycle. This legal framework is complemented by packaging regulations that aim to reduce environmental impact and promote a circular economy.

Every member state of the EU has accepted the WEEE Directive under its national laws, leading to a patchwork of compliance mechanisms and reporting obligations. Consequently, exporters and manufacturers must register for WEEE and potentially for packaging waste with approved national compliance schemes. Neglecting to comply with local regulations places your business at risk of penalties, import delays, or, worse, removal from certain EU marketplaces.

In addition to fulfilling your legal obligations, precise adherence to WEEE protocols can help you optimise EU WEEE margins by identifying areas where cost savings or efficiencies in reporting and logistics may be realised. For companies navigating multiple categories of electronics, each with its own thresholds and classifications, having granular control over documentation and accounting is non-negotiable. That’s why proper integration of EPR workflows into supply chain operations is more than just administrative—it’s strategic business planning. Learn more about EU EPR & Marketplace Compliance for Sellers

How EPR Fees Affect Your Profit Margins

Breakdown of Cost Structures and Margins

When calculating EU WEEE margins, businesses need to examine multiple variables—including product weight, material composition, and unit volume—which directly impact the fees levied by national compliance systems. EPR fees are generally structured around annual tonnage declarations, which separate costs based on specific product categories such as display devices, small equipment, large white goods, or lighting units.

Each of these categories attracts a different tariff, depending on the treatment and recycling effort required. For instance, complex items containing hazardous substances may incur exceptionally high WEEE fees. Additionally, packaging materials such as plastics, cardboard, and composites are also tariffed, bringing another dimension to your cost management strategy.

Margins are particularly vulnerable for products that are low-cost and high-volume. In such cases, even minor inaccuracies or underestimations in reporting could impact profitability significantly. Conversely, efficient logistics planning, sustainable packaging redesigns, or intelligent bundling strategies can drive down EPR-associated costs by optimising packaging weight and volume per shipping unit.

Accurate product classification and lean packaging design are two of the most powerful levers for improving EU WEEE margins across the board.

Country-by-Country EPR Obligations

One of the more nuanced challenges in managing EU WEEE margins lies in understanding how wildly different national implementations of EPR principles can be. For instance, Germany’s Stiftung EAR requires precise categorisation and advanced registration, while France’s Eco-systems demands dual registration for WEEE and household packaging compliance. Austria and the Netherlands apply weight-based thresholds before EPR applies.

Producers selling across multiple territories must work with local authorised representatives or compliance agencies in each country. It’s vital to avoid duplicative efforts and redundant registrations. A unified data management approach ensures accuracy across jurisdictions and unlocks the opportunity for consolidated declarations, where legally permissible.

Failing to align with local statutes not only risks compliance penalties but may also increase your costs due to fragmented operational planning. A centralised system for managing country-specific obligations, ideally with regulatory updates built in, proves invaluable for larger enterprise operations looking to scale within the EU. Read a related article

Best Practices for Reducing Packaging Costs

Reducing packaging expenditure plays a critical role in managing EU WEEE margins. Smart strategies begin with sustainable design. Replacing multi-material packaging with mono-material alternatives not only facilitates recycling but also lowers compliance fees. Using collapsible or modular designs that reduce total shipping volume yields further benefits in logistics costs.

Procurement also deserves attention. Source lightweight, eco-certified materials from verified EU suppliers where possible. Many compliance schemes reward sustainable materials with lower tariffs. Additionally, evaluating shipment fills can expose space inefficiencies—correcting these through intelligent package engineering directly impacts tonnage declarations.

Another often-overlooked tactic is periodic review and renegotiation with your packaging suppliers. Pricing contracts based on market rates, material innovations, or bulk economies can create room for operational cost reduction. Collaborate with your supply chain and sustainability teams to continuously monitor technology and trends that support greener, lighter, and cheaper options.

Automating Your EU EPR Process

Successful businesses increasingly leverage automation tools to optimise administrative processes involved with EPR compliance. Digital platforms can now streamline product data management, fee calculation, and multi-country reporting, removing scope for human error and significantly reducing clerk time.

An intuitive EPR compliance system should support SKU-level categorisation, automatic threshold detection, and real-time validation against current national legislation. Platforms such as SAP EHS, Enablon, or SERM provide robust EPR modules for enterprise users while digital-first compliance agencies offer scalable tools for SMEs.

Automation not only ensures consistency and traceability of your records but also unlocks predictive intelligence—spotting inefficiencies or pattern deviations that may affect EU WEEE margins. Investing in such infrastructure is, therefore, not just a compliance exercise but a sustainability and profitability strategy rolled into one. Optimising WEEE recycling strategies in Europe

How to Forecast and Calculate EPR Fees

Forecasting WEEE and packaging fees with precision is crucial for budget planning and margin protection. Begin by plotting historical data trends across product categories and match them against upcoming sales forecasts. Consider variables such as changes in market demand, product launches, and distribution network adjustments that could alter volumes.

If you are entering new markets or launching new product types, simulate EPR impacts using available fee calculators provided by member state compliance schemes. Adjust pricing models for each SKU to reflect true landed costs, inclusive of potential WEEE or packaging fees, thereby maintaining realistic gross margins.

Don’t overlook potential currency fluctuations and their effect on estimated fees—especially where declarations are pegged to Euros but your reporting currency differs. Taxation, trade laws, and recycling charge changes must also be factored into your three- to five-year profitability projections.

Product Classification and Its Impact on Fees

Precise product classification is indispensable in managing EU WEEE margins effectively. Misclassification can result not only in regulatory penalties but also in inflated compliance fees. WEEE categories span over ten classifications, each with distinct rules. For example, IT equipment, white goods, and photovoltaic panels each have unique reporting requirements.

Some items may even fall into dual categories: for instance, a smart refrigerator includes both cold appliance and IoT (internet of things) electronic components. In such cases, an incorrect categorisation might impose higher tariffs due to the mistaken assumption of hazardous components present in quantities that don’t exist. Conducting regular reviews with compliance specialists and maintaining alignment with the evolving EU WEEE directive is, therefore, critical.

Deploy HS code databases, cross-reference EU taxonomy tables, and engage in upstream supplier dialogues for technical specifications where ambiguities arise. The investment in doing so pays dividends over time by enhancing compliance predictability and margin control. Understanding EU Responsible Person obligations

Group Registrations & Consolidated Reporting

For corporations operating across multiple EU countries or with numerous subsidiaries, aggregated EPR management can deliver efficiency. Group registrations combine entities under a single representative and allow for consolidated fee reporting, simplifying accounting and often resulting in better EU WEEE margins.

However, not all member states support consolidated reports. Where available, ensure that intercompany data flows are structured around common data templates. This allows rolling up disparate declarations into unified reports without manual consolidation, which remains error-prone and time-consuming.

Engaging a pan-European compliance partner can also reduce multilayered administrative overheads, offering scale advantages while ensuring statutory conformity. Always verify that your structure is legally acknowledged and pre-approved by the national authorities in all jurisdictions involved.

Cross-border Selling with EPR Efficiency

Cross-border e-commerce poses unique challenges and opportunities for optimising EU WEEE margins. Online marketplaces such as Amazon or Zalando now increasingly require suppliers to demonstrate EPR compliance certificates prior to onboarding or maintaining product listings.

The best approach is proactive documentation. Maintain EPR registration numbers, proof of scheme compliance, and declarations readily accessible for digital verification. Coordinate with fulfilment centres to ensure packaging configurations meet local norms, especially where re-labelling or repackaging occurs for regional operations.

Failure to manage EPR obligations can result in product takedowns, storage holds, or even bans from platforms—slashing revenue and hitting margins directly. A fully harmonised, multilingual EPR framework expedites returns processing, waste collection, and record keeping, all while strengthening supplier credibility across European sales channels.

Common Mistakes That Cause Overpayments

Many companies unwittingly overpay their EPR fees due to avoidable missteps. The most prevalent errors include incorrect category assignment, ignoring exemptions, double-counting product weights, or failing to consolidate packaging components intelligently across SKUs.

Another frequent oversight is not leveraging harmonised tariff reductions or exemptions for low-declaration thresholds and environmentally positive packaging innovations. Businesses must also avoid under-declaring quantities, as later corrections often lead to penalty surcharges that distort EU WEEE margins. Mistiming submissions, failing to update scheme preferences, or working without local partners also introduces inefficiencies.

Periodically bench-marking your declarations against peers and seeking third-party audits can help identify overpayments and reclaim fees through corrective filings. Strategic accuracy is not only good governance—it actively protects your bottom line.

Conclusion: Smarter Compliance, Better Margins

[CONCLUSION_CONTENT]

Great guide on optimising-weee-packaging-fees-eu-margins – Community Feedback

How do WEEE and packaging fees impact profit margins in EU sales?

WEEE and packaging EPR fees are charged per unit or weight, eating into profit margins if unmanaged. By forecasting and optimising registration, reporting, and supply chain efficiency, sellers can significantly reduce these costs.

What strategies help optimise EPR compliance costs?

Automating compliance, accurately classifying products, leveraging group registrations, and consolidating reporting can all help cut unnecessary fees and reduce administrative overhead across the EU.

Are EPR fees different across EU member states?

Yes, each EU country sets its own EPR schemes, obligations, and fee structures for WEEE and packaging. Knowing the specific rules and cost calculations for each market is key to minimising expenses.