About eldris

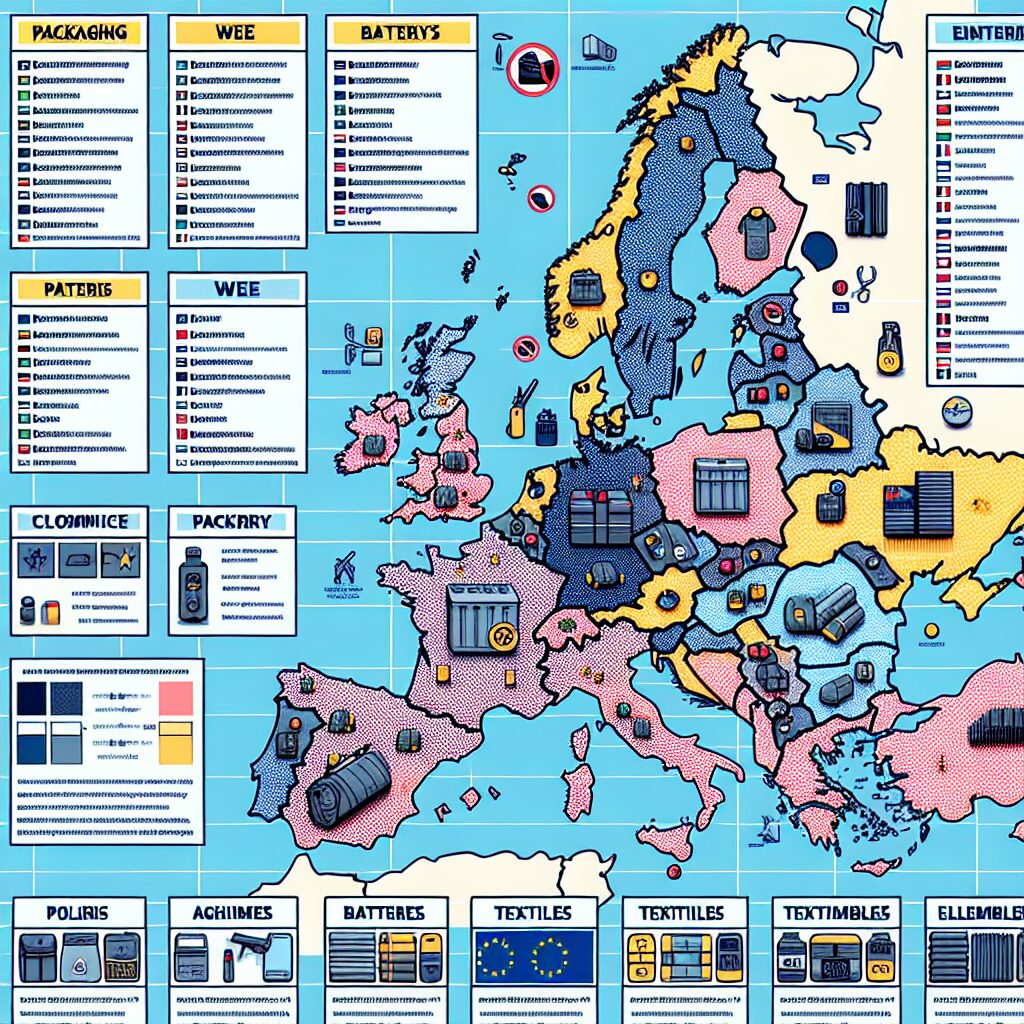

epr.eldris.ai leads the EPR sector, in fast, automated, AI Agent EU Complaince. LUCID Packaging, WEEE, and Battery Compliance for Brands, E-Commerce and Service based businesses expanding into the EU.

In This Article

- WEEE compliance is essential for selling electrical equipment in the EU legally.

- Quarterly reporting varies by country and format, requiring tailored submissions.

- Manual processes are prone to error and delay — automation vastly improves accuracy.

- Non-compliance can result in heavy fines and potential market access restrictions.

- Choosing the right EPR platform ensures audit-readiness and peace of mind.

- Staying informed of evolving regulations is critical to ongoing compliance.

What Is WEEE Compliance and Why It Matters

Helping Businesses Stay Environmentally Compliant in the EU

WEEE compliance refers to adherence to the Waste Electrical and Electronic Equipment (WEEE) Directive — European legislation aimed at reducing electronic waste and improving environmental outcomes. In today’s business climate, where sustainability and corporate responsibility are increasingly under public scrutiny, WEEE compliance plays a pivotal role. It ensures that producers, importers, and distributors of electrical and electronic equipment manage the end-of-life treatment of their products. Complying with this directive isn’t just a legal obligation but also a strategic advantage. Organisations that meet WEEE requirements demonstrate environmentally conscious stewardship, which fosters trust among stakeholders and avoids hefty penalties. Moreover, businesses expanding into Europe must understand how WEEE compliance affects product design, data reporting, and recycling obligations. Ignoring this directive can result in fines, reputational harm, or blocked market access. By implementing robust compliance systems, companies can streamline their product lifecycle management while contributing positively to EU sustainability goals.

The Quarterly Reporting Requirement

Deadlines, Formats, and National Submissions

Each EU Member State enforces the WEEE Directive slightly differently, but one commonality across the bloc is the obligation of quarterly reporting. Businesses that place electrical or electronic equipment on EU markets must submit periodic filings detailing product sales, category classifications, and quantities placed on the market. These reports are typically due within 15 to 30 days of the quarter’s end, depending on the country. The data submitted assists national environmental agencies in tracking domestic targets for equipment recycling and reuse.

However, the structure of quarterly reports can vary. Some regulators require submissions via custom portals with XML formatting, whereas others allow spreadsheet uploads or mandated PDF templates. Thus, organisations operating across multiple EU jurisdictions face a labyrinthine task of tailoring outputs for each national system. Mistakes in formatting, incorrect categorisations, or missed deadlines can lead to audit queries or increasing regulatory pressure. As a result, having a clear roadmap and automated tools in place is essential for businesses striving for seamless WEEE compliance reporting.

Common Challenges in WEEE Quarterly Filing

What Producers Often Struggle With

WEEE compliance involves more than simply submitting data — it revolves around managing complex processes efficiently. Companies frequently encounter challenges around data consolidation, especially when operating across multiple sales channels and logistics partners. Poor internal data hygiene can create inconsistencies in product identifiers, making it difficult to generate standardised reports.

Another persistent pain point is staff training and resource allocation. Managing WEEE filings often falls outside the core responsibilities of accounting or logistics teams. Without adequate training, personnel may mishandle national categories — for example, misclassifying lighting products as small IT and telecommunications equipment. Such errors, while seemingly minor, can create cumulative discrepancies within national recovery targets. Furthermore, WEEE legislation has evolved rapidly in recent years, and staying abreast of the regulatory landscape adds further complexity.

Automating WEEE Compliance: A Smarter Solution

Reduce Errors and Save Time Across Submissions

As the volume of reporting increases, automation emerges as the logical path forward. Software solutions tailored for Extended Producer Responsibility (EPR) regulations can centralise data collection across departments, automatically assign products to WEEE categories, and generate country-specific output formats. This automation dramatically reduces room for human error and accelerates reporting workflows.

Moreover, smart compliance platforms often include built-in notification systems to alert users ahead of regulatory deadlines. These automated reminders, coupled with real-time status dashboards, ensure that no submission is overlooked. For multinational companies handling WEEE data in 10 or more countries, automation helps mitigate translation bottlenecks and country-specific data formatting requirements. In short, automating WEEE compliance results in smoother workflows, fewer administrative burdens, and greater confidence during audits.

Choosing the Right Compliance Platform

Key Features in EPR Automation Tools

When evaluating a WEEE compliance platform, companies should consider several non-negotiable features. First and foremost, the system should offer multi-country support, allowing users to configure localised rules and report templates for each target market. Real-time data synchronisation is another crucial capability, as it enables businesses to reflect changes in product inventories, labelling, or supplier attributes without manual intervention.

Best-in-class platforms also include a rules engine to validate data before submission, flagging outliers such as zero-quantity listings or misclassified product codes. In addition, integration with ERP systems like SAP, Oracle, and NetSuite ensures that transactional data flows automatically, keeping filings consistent with broader financial records. Ultimately, the ideal platform delivers end-to-end assurance — from back-end data consolidation to front-end regulatory submission. Avoiding fines and achieving audit readiness becomes dramatically easier with the right digital solution in place. Learn more about EU Extended Producer Responsibility Compliance

Regulatory Variations Across the EU

Understanding Country-Specific Filing Differences

The WEEE Directive serves as a high-level framework, but enforcement lies at the national level. For example, Germany mandates reporting through the EAR portal, which requires companies to register and submit data via specific XML schemas. In contrast, Italy’s WEEE Centre focuses more on weight-based categorisation with direct uploads in Excel format. Failure to adhere to national expectations can result in submissions being rejected outright.

In some cases, the scope of obligated products differs. One country may include spare parts or cables under WEEE, while another may exempt them. Furthermore, reporting categories — the ten WEEE categories standardised by the EU — may not always map directly to local classifications, introducing complexity in cross-border reporting. Businesses need not only sophisticated tools but also strategic guidance when navigating country-specific nuances. Guide to understanding current WEEE obligations provides an up-to-date regulatory tracker that many businesses find indispensable.

What Penalties Exist for Non-Compliance?

Potential Fines and Market Access Risks

The cost of ignoring WEEE compliance goes beyond regulatory slaps on the wrist. Member States impose fines ranging from €5,000 to €100,000 for non-compliance, depending on the severity and duration of violations. Deliberate evasion or persistent under-reporting can lead to criminal liability in jurisdictions such as France or Spain.

Even more detrimental is the risk to market access. In several countries, non-compliance may result in suspension of product listings or a legally mandated halt on shipments. Retailers and distributors often require proof of compliance before continuing business relationships. Thus, companies that fall foul of WEEE legislation not only face fines but also reputational damage and lost revenue opportunities. Investing upfront in compliant practices is both a safeguard and a catalyst for growth. Read a related article

Tracking WEEE Directive Updates and Amendments

How Businesses Stay Informed

Directive 2012/19/EU laid the groundwork for current WEEE strategies, but updates continue to be issued. National agencies regularly modify reporting thresholds, revise classification codes, or expand the list of obligated equipment. Keeping abreast of these shifts demands active engagement.

Many successful companies subscribe to industry newsletters, attend compliance webinars, and leverage professional networks to gather intelligence on upcoming rule changes. Leading compliance platforms also include regulatory monitoring tools, which provide real-time updates on any legislative amendments relevant to user configurations. With data-driven insights, businesses can take pre-emptive action rather than scrambling post-deadline. Being proactive is essential in maintaining uninterrupted compliance and market presence.

Benefits of Stress-Free Quarterly File Management

Operational Efficiency and Accuracy

Implementing structured WEEE compliance file management unlocks immense organisational value. Manual reporting is labour-intensive, error-prone, and difficult to scale. In contrast, streamlined quarterly file processes allow compliance teams to focus on strategic initiatives, while software handles repetitive validation and classification tasks.

Moreover, consistent formatting and centralised data repositories reduce miscommunication between departments. Environmental officers, financial teams, and procurement units can easily align on product strategies and packaging metrics. Accurate filings create cleaner audit trails, reducing time spent resolving regulator return queries. Ultimately, the goal is not merely meeting quarterly obligations but transforming compliance from a reactive headache into a proactive contributor to sustainability and corporate reputation.

Case Study: E-Commerce Brand Scaling in the EU

Real-World Use Case of Automation Success

Consider an e-commerce retailer headquartered in the UK, expanding into ten EU countries. Initially, their quarterly WEEE reporting involved contacting local consultants, juggling a patchwork of Excel templates, and dedicating three full-time staff to compliance tasks. Submission delays often resulted in fines ranging from €1,000 to €4,000 per country.

After onboarding an EPR automation platform, the company saw dramatic improvements. Product data from their ERP system was auto-imported, categorised, and converted into compliant formats for each Member State. Deadline tracking and submission confirmations were integrated into one dashboard. Within two quarters, they halved their compliance spend, reduced regulatory notices to zero, and achieved full audit readiness. More importantly, they freed up internal resources for expansion initiatives, transforming compliance from liability to growth enabler.

“Once we automated our WEEE compliance reporting, we saved hundreds of hours per year and eliminated submission errors altogether. It allowed us to focus on scaling our business, not chasing regulatory deadlines.”

Conclusion: Make WEEE Reporting Effortless

WEEE compliance is mandatory, but it doesn’t have to be overwhelming. By understanding your obligations, preparing for country-specific variations, and adopting automation tools, your organisation can transform compliance into a streamlined, strategic asset. Quarterly filings need not drain time or resources when supported by the right systems. Whether you’re a startup exploring European markets or a multinational with complex distribution networks, the right approach to WEEE reporting can lead to enhanced accuracy, improved efficiencies, and stronger stakeholder trust. As regulations grow stricter and enforcement more rigorous, digital-first compliance will separate leaders from laggards. Embrace automated compliance now — and make quarterly filing stress-free.

Great guide on weee-compliance-reporting-stress-free-quarterly-files – Community Feedback

What are the requirements for quarterly WEEE compliance reporting?

Producers must register, collect data on electrical equipment placed on the market, and submit quarterly reports covering amounts sold, collected, and recycled, to national authorities or compliance schemes.

How can automation simplify WEEE compliance for businesses?

Automation minimises manual entry, streamlines data preparation, ensures report accuracy, and reduces the risk of missed deadlines or errors in WEEE submissions, saving time for producers.

Are there penalties for late or inaccurate WEEE quarterly filings?

Yes. Non-compliance with reporting deadlines or providing inaccurate data can lead to fines, enforcement action, and losing market access in EU countries.